District heating – efficient and eco-friendly

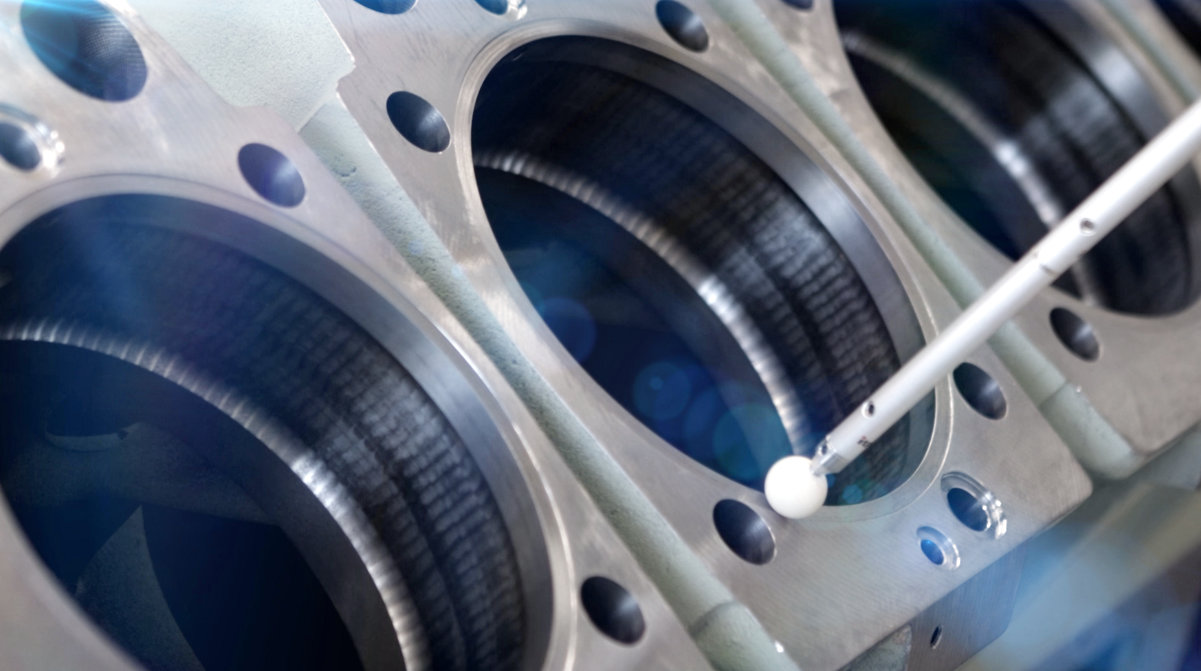

District Heating Power Plant Chilanzor, Uzbekistan

- Ideal for regional public utilities

- Simultaneous use of heat and electricity

- Energy efficiency of up to 90%

District heating – efficient and eco-friendly

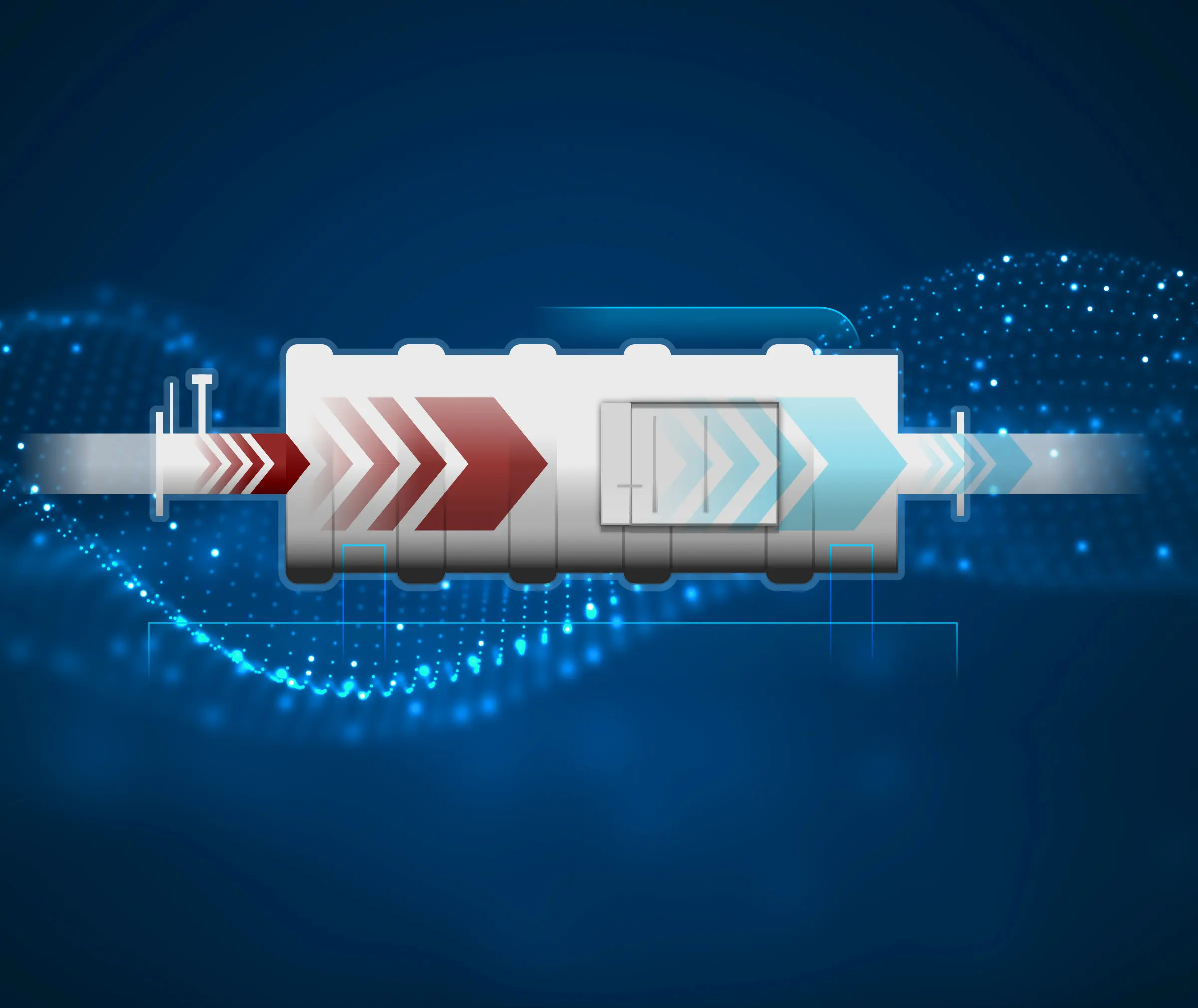

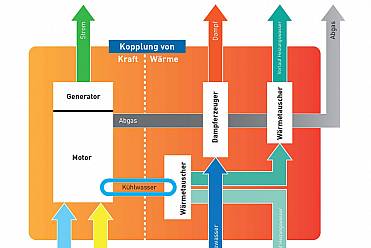

Combined heat and power, or cogeneration, is considered an eco-friendly technology as the simultaneous production of heat and electricity leads to significantly better utilization of primary energy compared to producing power and heat separately in boilers and large power plants. With a cogeneration percentage of at least 70%, the primary energy factor is 0.0–0.7 for electricity and heat from cogeneration power plants (CHP), depending upon the fuel used.

High efficiency thanks to district heating

While waste heat in a conventional power plant is released untapped via the cooling tower into the atmosphere, this energy can be utilized for heating purposes in combined heat and power (CHP), which allows for the high degree of energy utilization and the resulting higher efficiency of CHP. Today local and district heating is created almost exclusively through heat from cogeneration systems, making it the most efficient technology for large-scale heat supply. Combined heat and power not only allows us to cut the use of energy and raw materials but also to make a significant contribution towards lowering CO2 emissions.

District heating – electricity and heat generated by local energy producers

The advantage of local and regional energy generation lies in the ability to produce electricity close to where heat is needed. District heating is generally produced and distributed by providers through simultaneous generation of heat and electricity in large cogeneration power plants connected to a local or district heating system. In addition, cogeneration power plants (CHPs) have been deployed for many years that enable distributed use of this technology in companies, communities and larger residential buildings. Local use cuts energy losses otherwise created during the process of distributing electricity and district heating, which further improves the energy efficiency of cogeneration. More and more often, industry locations that generate lots of heat during production are also connected to existing district heating systems.

District heating – a proven technology for decades

The idea of producing district heating in a larger scope and on a commercial basis already originated at the end of the 19th century. Cutting the number of heat-producing plants in city centers lowered the risk of fires and reduced pollution due to coal and ash. While dedicated heating plants used to be deployed in the past, today predominantly modern combined heat and power plants supply heat into the networks. The heat created in these central heating plants is transported to the consumer via well-insulated pipelines.

MWM provides customized CHP packages and gas engines, the necessary mechanical equipment as well as controls to capture thermal energy from engines and transfer it to an industrial plant. The total energy cost savings of such systems can more than offset the total owning and operating costs, delivering a payback in as little as two to three years, depending on local energy pricing and policies.

The gamut of possible heat producers ranges from highly-efficient cogeneration power plants via waste incineration, right down to the gas-and-steam combined power plant with combined heat and power. Taking into account the variety of different heat generation models – central district heating, local heating supply in the form of “island solutions” and distributed heat production – there is a growing need for coordinated and integrated heating supply concepts.

Many areas of application

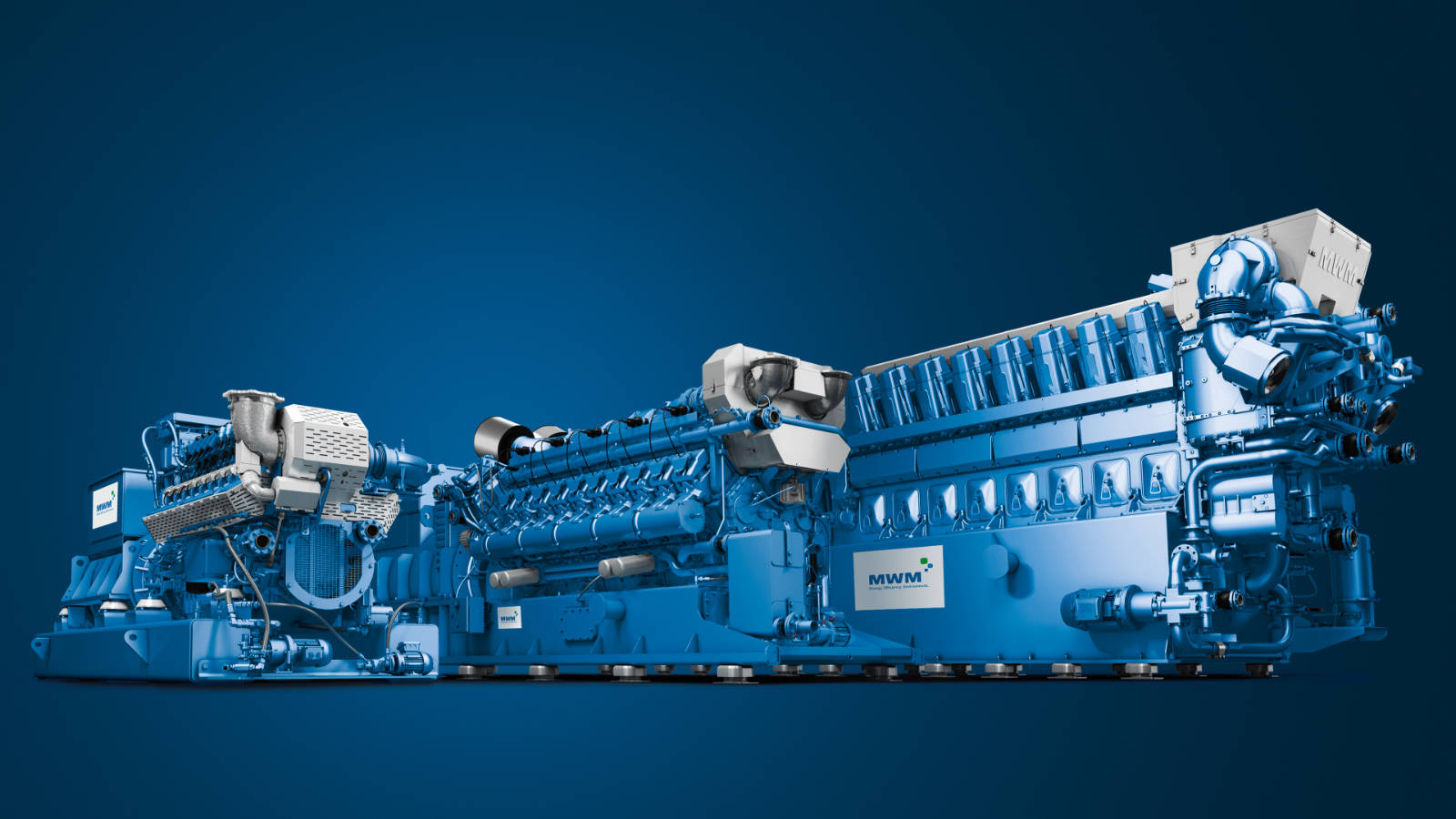

Gas powered gensets from MWM can simultaneously deliver electrical energy for electrical loads and heat energy for the heating of industrial plants. While the efficiency of separate grid power and natural gas boilers is often less than 50%, MWM’s district heating systems offer compelling advantages.

Advantages of MWM district heating systems

- Ideal for regional public utilities

- Highest efficiency and eco-friendliness thanks to highly-efficient, modern MWM gas engines

- Simultaneous use of heat and electricity

- Energy efficiency of up to 90%

- Lower energy costs than with separate heat and power generation systems

- Lower emissions than with separate heat and power generation systems

Gas Engines & Products

Cogeneration Power Plant Solutions

Eco-friendly MWM cogeneration power plants with combined heat and power enable decentralized, economical and energy-efficient power production.

Gas Engines / Generator Sets

Gas Engines, gensets, biogas and natural gas generator sets, Power Generators for decentralized energy supply by MWM, one of the world's leading providers of highly efficient, eco-friendly plants.

Contact Sales & Service

MWM Austria GmbH Archengasse 24C A-6130 Schwaz Austria

T +43 5242 21300 E info-austria@mwm.net

W www.mwm.at